AWS Supply Chain Services

The Amazon Web Services (AWS) supply chain has been an integral part of Amazon’s success, allowing them to rapidly scale their operations and expand into new markets. As the demand for Amazon services grows, so does the need for robust and reliable supply chains that can keep up with the ever-changing needs of customers. In response to this growing demand, AWS has recently unveiled new and improved features that are designed to make supply chain management easier and more efficient for the businesses.

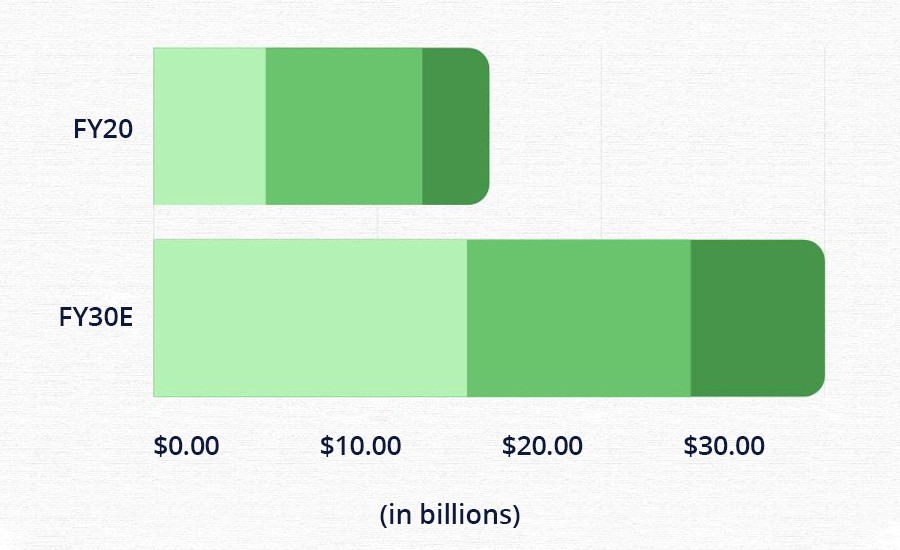

According to the report, the global cloud supply chain management market was estimated at $4.4 billion in FY 2020 and is expected to grow at a compound annual growth rate (CAGR) of 20% to $27.24 billion by FY 2030. Amazon has also introduced its AWS supply chain management services, which is a cloud-based machine learning application that assists businesses all over the world in making their supply chains more functional, reducing the risk of failure in inventory management, and lowering costs by taking real-time decisions. It provides an integrated solution to manage all the logistics work, such as freight, warehousing, packing, deliveries, etc., in one system.

The global cloud supply chain management market is expected to grow at a CAGR of 20% from FY20 to FY30.

In this article, we will be taking a closer look at the AWS supply chain process, AWS supply chain solutions , and the benefits of deploying the AWS supply chain application by businesses across the globe.

The AWS Supply Chain Process

It is a cloud-based and machine learning (ML) powered platform for providing insights on supply chains and collaboration processes. It integrates with companies' ERP and supply chain software, so there is no need to reinstall the system or pay upfront licensing fees, and it provides the benefits of short-term contracts for service checking.

The detailed four steps that help in the successful implementation of AWS supply chain cloud software by a business are as follows:

-

Data Extraction

The first step involves taking the data of the businesses from their already installed ERP platforms, supply chain software, and EDI, which includes purchase orders, invoices, shipping details, payment information, and others.

-

Deploying the AWS Software

The second step is to employ the AWS supply chain solutions which is a cloud based and ML-powered application.

-

Data Transformation

The third step involves the automated transformation of the company’s data. It is a step toward better integration of the company's data and the AWS features that are applied to that data.

-

Data Loading

In the data loading process, there is an insight into the inventory data of a company with the help of AWS supply chain management , collaboration among the team members, vendor lead time predictions, and demand forecasting, thereby creating the AWS Supply Chain data lake.

-

Observations and Network Mapping

It gives business owners details of excess stock and stock outs from all warehouses and locations over the last few days, as well as new insights. They can also create a customized watchlist by selecting the location, risks, statuses, largest deviation from threshold stock, and soonest impact, which are highlighted by AWS ML software.

It also provides real-time visual network mapping across different locations, keeps a check, and provides the details of inventory on hand, safety stock, in transit, on order, allocated, or damaged. It also shows a graphical representation of the expected stock outs and excess inventory in the coming days.

-

Recommendations and Teamwork

It provides the recommended actions that can be taken by the business owners to reduce the risk of running out of stock or having excess stock of a single product in any location. They also compare the current inventory situation to provide details of the projected inventory at each location.

They also offer rebalancing options and how much inventory should be moved from one location with excess stock to another with a risk of stock out. It also provides benefits for collaboration among employees and managers who are in different locations, and they can chat with each other to provide inventory details in their warehouses, which are visible to everyone who has been added to the software.

-

Analysis of vendor lead time

It also forecasts vendor lead times, which is the time from when a purchase order is placed until the goods are ready and available to sell or ship from the warehouse, so that inventory management becomes more efficient, and helps identify which activity between the order placement, and shipping is taking more time.

-

Forecasting demand

Demand planning is based on historical data to project future demands. It also gives a range of projected upper and lower bounds for the future. This data changes on a real-time basis, which helps the managers plan everything appropriately.

-

AWS Data Lake

AWS supply chain data lake takes the information and differentiates it based on non-transactional data and transactional data, which is a centralized repository that can store and process a large amount of structured or unstructured data.

In transactional feeds, data is automatically differentiated based on company, geography, product type, reference, or vendor management. In the non-transactional feed, data related to inventory management, and outbound details such as order fulfillment, packing, shipping, delivery, and customer service are included.

AWS Supply Chain Solutions

AWS has taken the lead in supply chain management, introducing a variety of new features and tools that are designed to make supply chain management easier and more efficient. With WMS, OMS, and SMS, businesses can better manage their inventory, orders, and suppliers, allowing them to optimize their supply chain and better serve their customers. These new features of the AWS supply chain management are helping to create a more efficient and cost-effective supply chain system, ensuring that businesses can keep up with the needs of their customers.

-

AWS Warehouse Management System (WMS)

This system is designed to help businesses of all sizes better manage their inventory, from tracking product availability to optimizing storage and shipping. With the WMS, businesses can easily view their inventory levels, order status, and shipping schedules in real time, allowing for better decision making and improved efficiency throughout the supply chain.

-

AWS Order Management System (OMS)

This system enables businesses to manage their orders in a more organized and efficient manner. With the OMS, businesses can easily view the status of their orders, track the progress of shipments, and analyze customer data to identify potential areas of improvement. This system provides business owners with insights and helps them make informed decisions about their supply chain, allowing them to better serve their customers.

-

AWS Supplier Management System (SMS)

AWS also provides a set of tools for managing supplier relationships, so businesses can easily track their suppliers, monitor their performance, and evaluate their performance against industry standards. This system helps businesses make sure that their suppliers are meeting their expectations and can help them identify potential areas for improvement.

Benefits of using AWS Supply Chain Services

Here are some of the benefits that a business can get by choosing AWS cloud-based supply chain services:

-

Increases visibility:

It helps in increasing the visibility of supply chains to the managers, and the AWS cloud software can be easily integrated with a company’s functional platforms without paying any extra fees or entering into any long-term contractual agreements.

-

Informed decisions:

It helps in making informed decisions by providing details on stock levels at every location and also forecasting the levels of inventory on a real-time basis.

-

Error reduction:

It reduces the risk of stocking out or holding excess inventory. It provides chatting and messaging services on the same platform to improve coordination across teams in different locations and help resolve the issues in a quick way.

-

Less costly:

It also provides a free trial and different packages for customization in data storage, inventory insights, and demand planning services, which helps reduce the overall cost. It also provides the AWS pricing calculator, which calculates the estimated cost a company will incur by utilizing various AWS supply chain services and planning based on their budget.

Conclusion

Therefore, choosing AWS supply chain solutions by manufacturing, industrial, e-commerce or retail businesses across the world will clearly optimize their supply chain process, as it helps in providing real-time analysis on demand and supply of stocks, better integration and collaboration across different locations, helping in the scalability of the business, increasing visibility in the supply chain, automating procurement, reducing costs, and lowering the possibility of being unable to deliver the goods by the deadline.

Cloud IBN offers a range of services in migration of on-premises apps to cloud or set up a hybrid cloud and on-premises server solutions. Manoj Oswal is the Vice President at IBN Technologies Limited and has over 28 years of experience in setting up information technology solutions. We are also one of the standard AWS partners and have certified AWS experts working on our team.

Frequently Asked Questions (FAQs)

How does the cloud help the supply chain?

Cloud computing is the new trend in supply chain management, which helps businesses automate processes at all levels, including integration, planning, manufacturing, logistics, packaging, shipping, and distribution, and construct strong and smart supply chains that are globally connected, scalable based on needs, improve visibility and flexibility, and provide rapid product delivery.

What are the 5 biggest supply chain issues?

The five biggest issues in the supply chain are the high cost of transportation and warehousing, the longer lead time between getting the order and actual delivery, managing the relationship with suppliers, providing good customer service, and reducing waste and defects.

What is AWS SCM?

Amazon Web Services provides a cloud-enabled and ML-powered AWS supply chain management service that helps businesses monitor their supply chain remotely in order to reduce the risk of overstock and stock outs at each and every location on a real-time basis. It also provides suggestions on how to best handle the inventory in order to reduce inventory costs and ensure rapid delivery of products.